Dalhousie University Space Systems Lab spent four years constructing the first satellite made in Nova Scotia which is now ready to be launched into space.

The nanosatellite called "LORIS," which stands for Low Orbit Reconnaissance and Imagery Satellite, will be launched in August and predictions show it will orbit the Earth for about 12-14 months. Then, after re-entering Earth's atmosphere at its usual speed of 400 km, it will vaporize into the atmosphere.

The LORIS was put on displace Thursday from 3-5 p.m. at 5283 Morris St. in Emera IDEA Building on the Dalhousie campus. Founder of GALAXIA Mission Systems and Dalhousie Space Systems Lab Arad Gharagozli said the purpose of the satellite was to showcase a lot of Dalhousie’s technology.

“The project started in 2018 and took about four years to do. We had more than 250 students involved in it. And the purpose of it is a lot of technology demonstration. At Dalhousie, we did a lot of research and development that went into space. So the satellite will bring those into space. And then we can monitor the status of those systems we have designed and see how they perform in that environment.”

The Nanos satellite class, the smaller version of a typical traditional satellite, is the first satellite ever designed in Nova Scotia up to date.

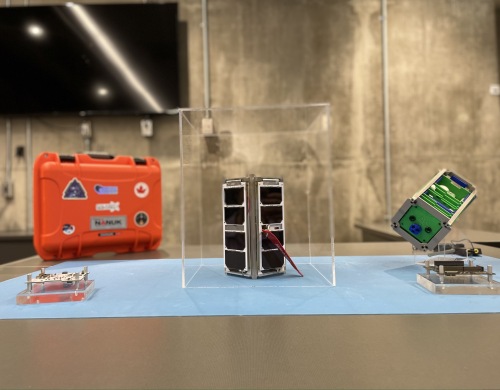

Left to right: The prototype power supply system used to show what the boards inside the satellite look like, LORIS, the motherboard, 3D printed satellite out of plastic used to demonstrate the inside of a fully assembled satellite. Photo by Sara Gouda.

This project was funded by the Canadian CubeSat Project (CCP). The CCP funded this project for universities across Canada to design and build a nanosatellite that can go to space, with all research and development attached.

Gharagozli said that COVID-19 caused some delays in the project, but that wasn’t the only challenge the team faced.

“It was full of challenges and full of mistakes and full of errors and things that we had to redo and break and redesign and rethink. But that's a very good thing, because that just shows us how much we have learned from them.”

The grant the project received from the Kennedy Space Agency was $200,000. The budget was aimed toward risks, a stipend for master’s students, material labs, travelling costs for the project and similar requirements. The cost of the satellite is estimated somewhere between $50,000 and $65,000.

Dalhousie University student Kenzie Timmons, the mechanical lead for LORIS, said the main goal of the project was to teach undergraduate students what the space industry is like, and to learn how to develop a satellite from scratch.

“We’re using the different control systems to point within Nova Scotia and its surrounding oceans, then take a picture in both visible and near infrared light, and then beam it back down to Dalhousie to look at.”

Kenzie Timmons, LORIS mechanical lead, said his role specifically was to design the main chassis and all the mechanical components with it. It is also to conduct a finite element analysis to ensure that it can handle both the static loads and vibration loads of the rocket launch, as well as a thermal analysis for in space ensuring everything is within the temperature. Photo by Sara Gouda.

Abdulbasit Syed, lead systems engineer for LORIS, said he has been working on this project for almost three years.

“It was a great learning experience and we have a great team. It's definitely a dream come true to see the satellite in person, all assembled and ready to go.”

Listen to the CKDU story below: